Hardware Resources

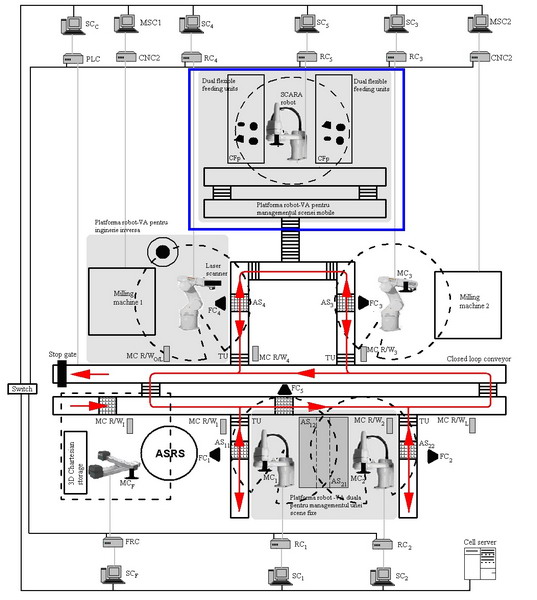

1. The already existent system In the robotics laboratory an intelligent assembly cell composed of several working stations joined together by a transportation system is already installed, as a result of previous projects. All this cell is controlled by a Bosch Rexroth IndraLogic PLC and an IBM Cell Server (see the figure). The present project proposes to extend this structure with an extension for part supplying (marked in blue). The role of this extension is to take bulk parts and to place them on the pallets in order to supply the working stations. These extensions will be building around an Adept Cobra S800 robot that will take the parts supplied by two Adept AnyFeeders; also it will attack the problem of picking up and placing a part on a movable pallet. This extension will be controlled by its own Bosch Rexroth IndraLogic PLC and will be compatible with the pallet movement/ tracking system already installed.

Fig.1. System and extension structure 2. Conveyor The implemented conveyor will be the same as in the already existent cell. This conveyor will transport the pallets to their correct destinations. a) Workpiece Pallet

b) Longitudinal conveyor

c) Leg Set

e) Transfer unit

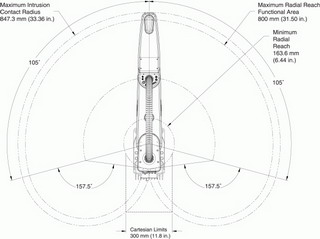

3. Horizontally articulated robot The Adept Cobra™ s800 SCARA robot is a high-performance SCARA robot system for mechanical assembly, material handling, packaging, machine tending, screwdriving, and many other operations requiring fast and precise automation. The manipulator is directly driven, the motors operate without reducers. The Adept Cobra s800 SCARA robot offers maximum flexibility and scalability, a dramatic 70% reduction in wiring over other SCARA robots, and unique cost-saving expansion capabilities that are only available with Adept SmartServo. The Adept Cobra s800 SCARA robot supports high-performance options, including conveyor tracking, vision guided motion, auxiliary servo axes, general machine control.

Fig.7.Adept Cobra 800 Technical data

4. Teach pendant The Adept T1 Pendant provides a user interface and teach pendant in an ergonomic and rugged package. The T1 Pendant was designed for right-handed and left-handed use. All gripping and holding positions enable comfortable and fatigue-free operation.

Technical data

5. Robot controller The Adept SmartController™ CX is a high-performance robot and vision controller based upon Adept SmartServo architecture. Its distributed processing architecture improves performance by freeing up 30% of the processor’s resources. The Adept SmartController CX features a faster processor and conveyor belt tracking support, and optional vision guidance support. It also features several high-speed communication interfaces, including Fast Ethernet and SmartServo™. A single SmartController™ CX can control up to 2 robots through the SmartServo communication ports.

Technical data

6. Conveyor controller The IndraLogic L40 PLC solution is based on the innovative IndraControl L40 embedded terminal control. A number of communication interfaces simplify the integration with various control structures. Expansion with function modules enables flexible adaptation to requirements for various applications and processes. The I/O periphery is easily expandable by direct connection of Rexroth Inline modules. User-friendly and programmable using IndraWorks engineering software that is IEC 61131-3 compliant. Diagnostics are easily performed using IndraWorks or locally using the control’s integrated display.

Technical data

7. Identification system

Identification and data storage systems are used for controlling numerous production and transport systems in assembly technology. On the one hand, data related to objects is the basis for targeted control of process and processing steps and, on the other, is used for type or variant-dependent infeeding and outfeeding of workpiece pallets when manufacturing product variants on flexible assembly systems with branches.

Technical data

At each crossroad there is a read/write head who alters the information contained within the data carrier.

Technical data

The processor supervises the bi-directional data transfer between data carrier and read/write head and serves as buffer storage. It is the link between the host system and the data carrier.

Technical data

8. Basler A601f video camera The Basler video camera is an industrial camera supported by Adept. The camera communicates digitally by the IEEE 1374 FireWire interface. Also, for accessing the inputs/outputs of the camera, an RJ45 10 pins connector is provided. Other characteristics:

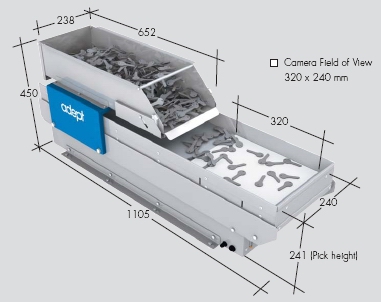

Fig.15.Basler video camera 9. Adept AnyFeeder Adept AnyFeeder is a vibrant surfaces system that spreads out the bulk parts on a larger surface. This surface is inspected by a camera that enables the robot to catch the parts. The undetected parts are vibrated in order to turn them on the other side or to change their position relative to each-other, after witch the detection process is restarted. Main characteristics:

Fig.16.Adept AnyFeeder |

|

|---|

Last update : 11.11.2009